Metropolitan Insulation Resources

Technical Performance from Metropolitan Insulation

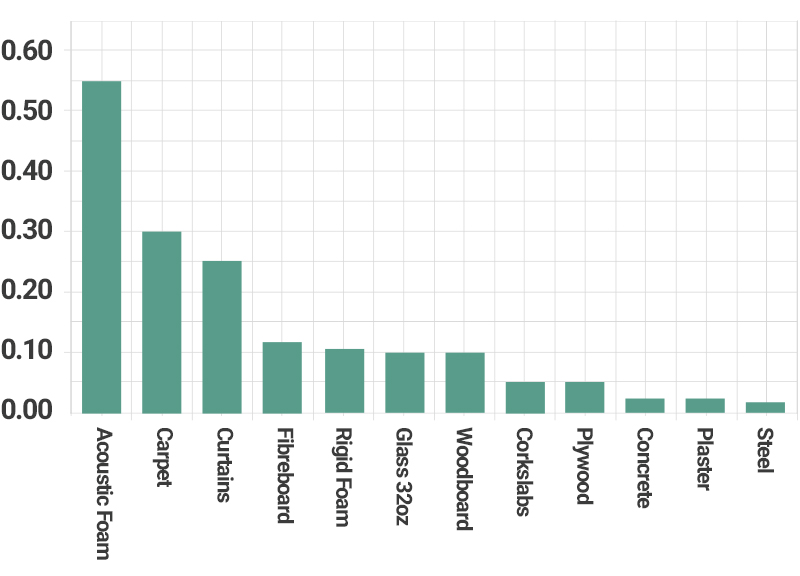

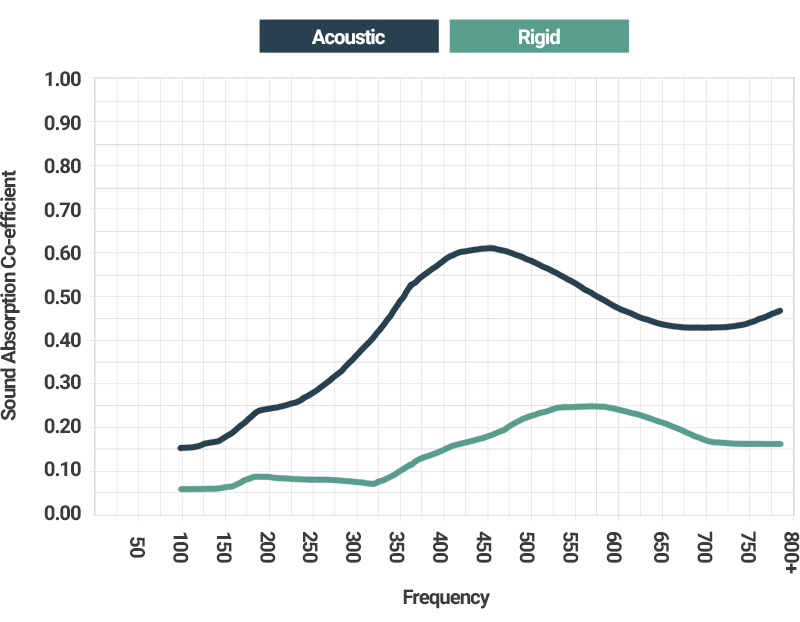

The test results opposite from the University of Salford show clearly that the Capital system absorbs >50% of the sound energy impacting the test surface. A co-efficient of 1.00 represents total absorption.

| Sound Absorption Co-efficient | ||||

|---|---|---|---|---|

| Material | 125hz | 500hz | 2000hz | 4000hz |

| Acoustic Foam | 0.12 | 0.55 | 0.38 | 0.43 |

| Carpet | 0.1 | 0.3 | 0.5 | 0.6 |

| Curtains | 0.05 | 0.25 | 0.3 | 0.4 |

| Fibreboard | 0.05 | 0.15 | 0.3 | 0.3 |

| Rigid Foam | 0.01 | 0.11 | 0.14 | 0.11 |

| Glass 32oz | 0.2 | 0.1 | 0.05 | 0.02 |

| Wood Board | 0.15 | 0.1 | 0.1 | 0.1 |

| Corkslabs | 0.05 | 0.05 | 0.1 | 0.1 |

| Plywood | 0.05 | 0.05 | 0.05 | 0.05 |

| Concrete | 0.01 | 0.02 | 0.02 | 0.02 |

| Plaster | 0.02 | 0.02 | 0.04 | 0.04 |

| Steel | 0.1 | 0.1 | 0.1 | 0.1 |

The below table compares the relative sound absorbing properties of the Capital system and commonly used materials. A co-efficient approaching zero indicates that the material is reflecting the sound energy that impacts the test surface.

- External foam and coating systems in line with BS5241 and BS7021.

- Achieves U/values from 0.981 to 0.160.

- Class 1 surface spread of flame rating when tested in accordance with BS476 Part 7.

- Class 0 (higher than statutory Class 1) coatings available for additional fire resistance.

- All materials manufactured to ISO 9002.

- 10 – 25 year guarantees.

- Additional insurance bonded guarantees.