Welcome to

Metropolitan

Insulation Services

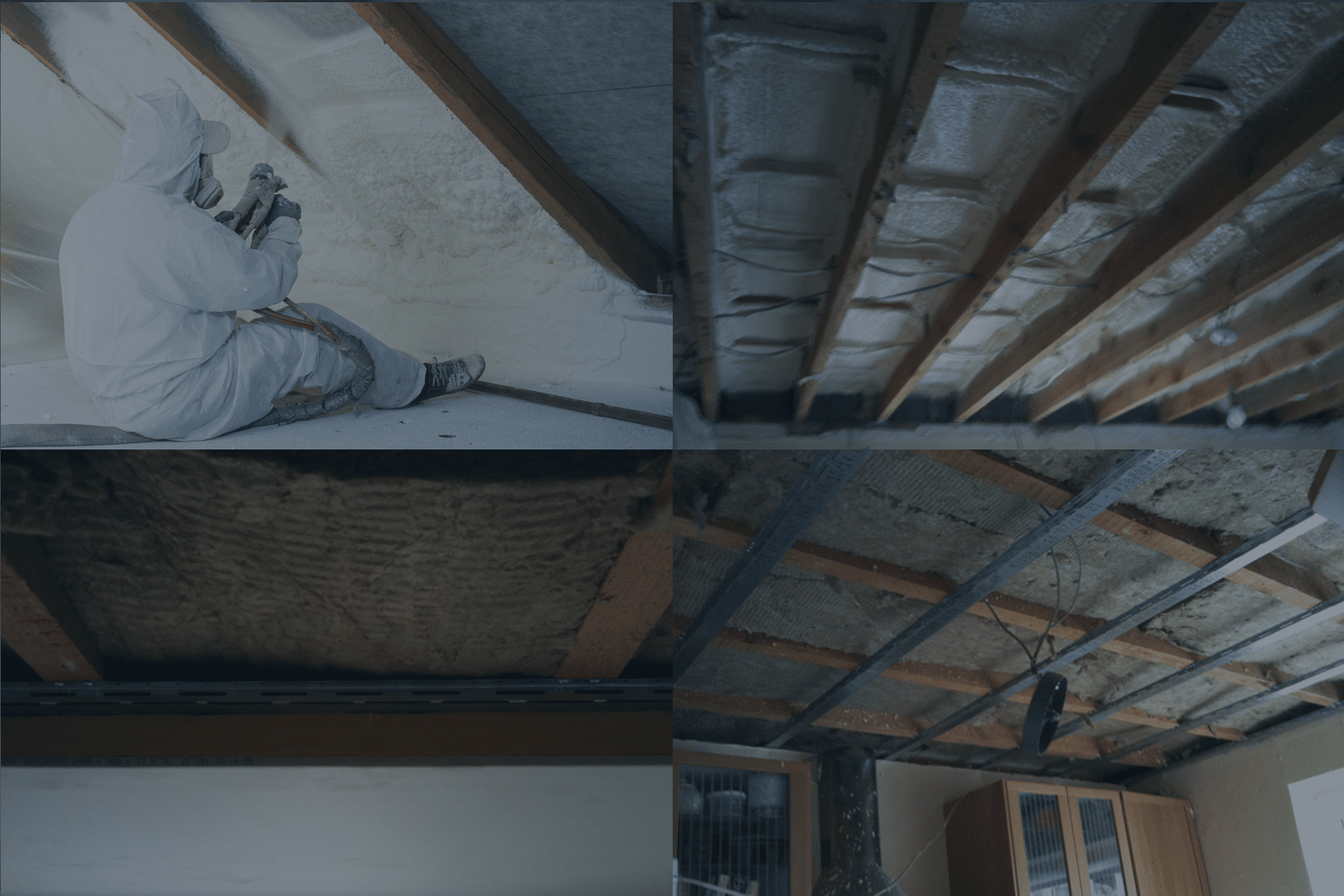

We are NATIONWIDE specialists in sprayfoam and injected solutions, soundproofing (acoustic) insulation and thermal insulation, flat roof solutions and asbestos encapsulation for commercial, industrial and domestic markets.

What We Offer...

- Free Expert Advice.

- Supply and Fit Solutions.

- Full Project Management.

- High Performance Applications.

- Green / Eco Friendly.

- No Fuss.

- Guaranteed Work.

- 30+ Years Experience.

Metropolitan Insulation; helping you to help the planet